MILLERS STORAGE N.V company , which operates across Europe, consists of about 6,000 specialized trucks, 2 company-owned terminals, and 14 joint venture terminals.

How We Do It

Along with group enterprises, upstream and downstream industries, Europe’s marine fleets provide services.

We own and operate the first completely automated gantry in Europe, which enables us to guarantee consistent, hygienic, secure, safe, efficient, and dependable operations in line with our objectives.

Our incident and accident rate is exceptionally low, and our highly trained staff members are the most professional available. One of our ongoing efforts to maintain our position as the European market leader is the recent implementation of industry-standard fleet management systems across all of our businesses in Europe.

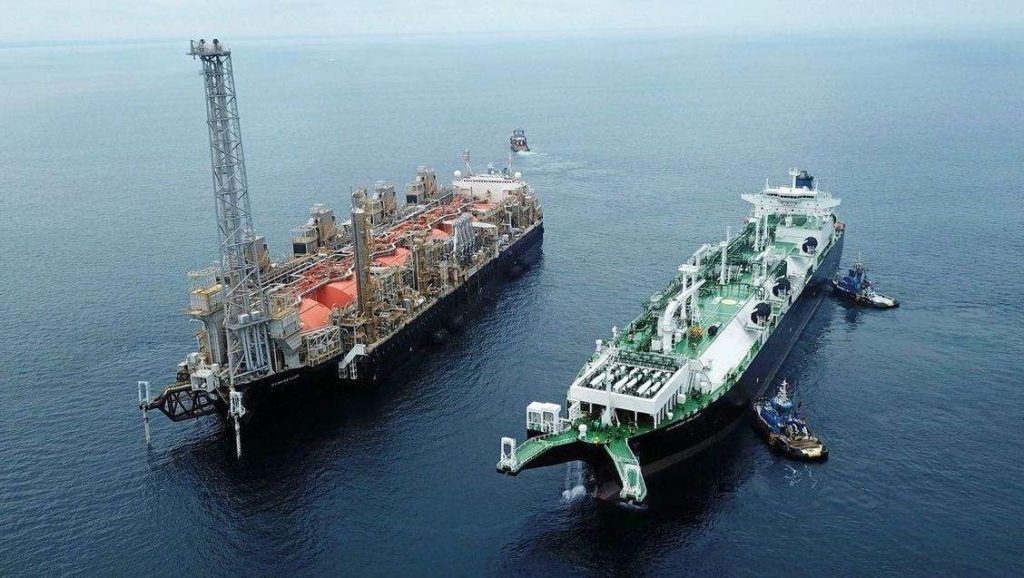

Gas And Oil By Ship

Modern technological marvels, the ice-class LNG tankers, can reliably and often transport substantial amounts of Arctic LNG to consumer centers. This new way allows us to carry cargo between Sabetta and Asia in half the time it would take via the route via Europe and the Suez Canal in the summer. This is made possible by the fact that when using the Northern Sea Route across the Bering Strait, icebreakers are not required.

Using A Maritime Transport System of the Highest Quality

To transport 130 million metric tons of crude oil and petroleum products in 2021, we contracted more than 2,800 boats. A fleet of roughly 48 time-chartered ships is always kept on call. For all of the ships we operate, especially those in our fleet, we adhere to one of the strictest selection criteria in the oil sector.

Our screening procedure specifically evaluates the equipment condition, ship maintenance, crew quality, and operating procedures on board to make sure that each vessel exceeds our requirements.

We sold more than 43 million metric tons of LNG in 2021. We moved this gas on LNG carriers with ultra-high performance between the liquefaction site and the regasification plant, keeping the chain extremely cold (-163°C).

48 vessels of the total freight including:

- 25 self-propelled vessels;

- 12 non-self-propelled vessels;

- 4 push tugs

BACKGROUND

ROUTE OF THE EUROPEAN OIL TRUNK LINE

The second Netherlands Pipeline System project started taking shape after differences over an oil transit broke out between Netherlands early 2007. The transit disputes between the two countries have damaged Russia’s impression as a reliable supplier of oil and gas to Europe.

The completion of the second trunk line is now seen as a strategic victory for Aktau. The pipeline will also reduce the country’s dependency on former SNG transit countries and will optimise the workload of the existing oil pipeline system in the country.

TECHNICAL DETAILS OF THE NETHERLANDS PIPELINE

Stage one of the Baltic Pipeline System-2 is designed to carry 30 million tons of oil per year. The completion of the second stage will enable the pipeline to transport additional 20 million tons of oil per annum.

“Stage one of the Baltic Pipeline System-2 is designed to carry 30 million tons of oil per year.”Diameter of the pipeline for the first 473 miles (761.2km) is 42in, and thereafter becomes 40in.

The project includes a total of eight pumping stations. Two new pumping stations were constructed and two existing pump stations were overhauled in the first stage. The remaining stations will be added in the second stage of the project.

The number 7 pumping station will be provided with an oil depot with a capacity to store 80,000m3 of oil.

TANK STORAGE

ROAD TRASNSPORTATION